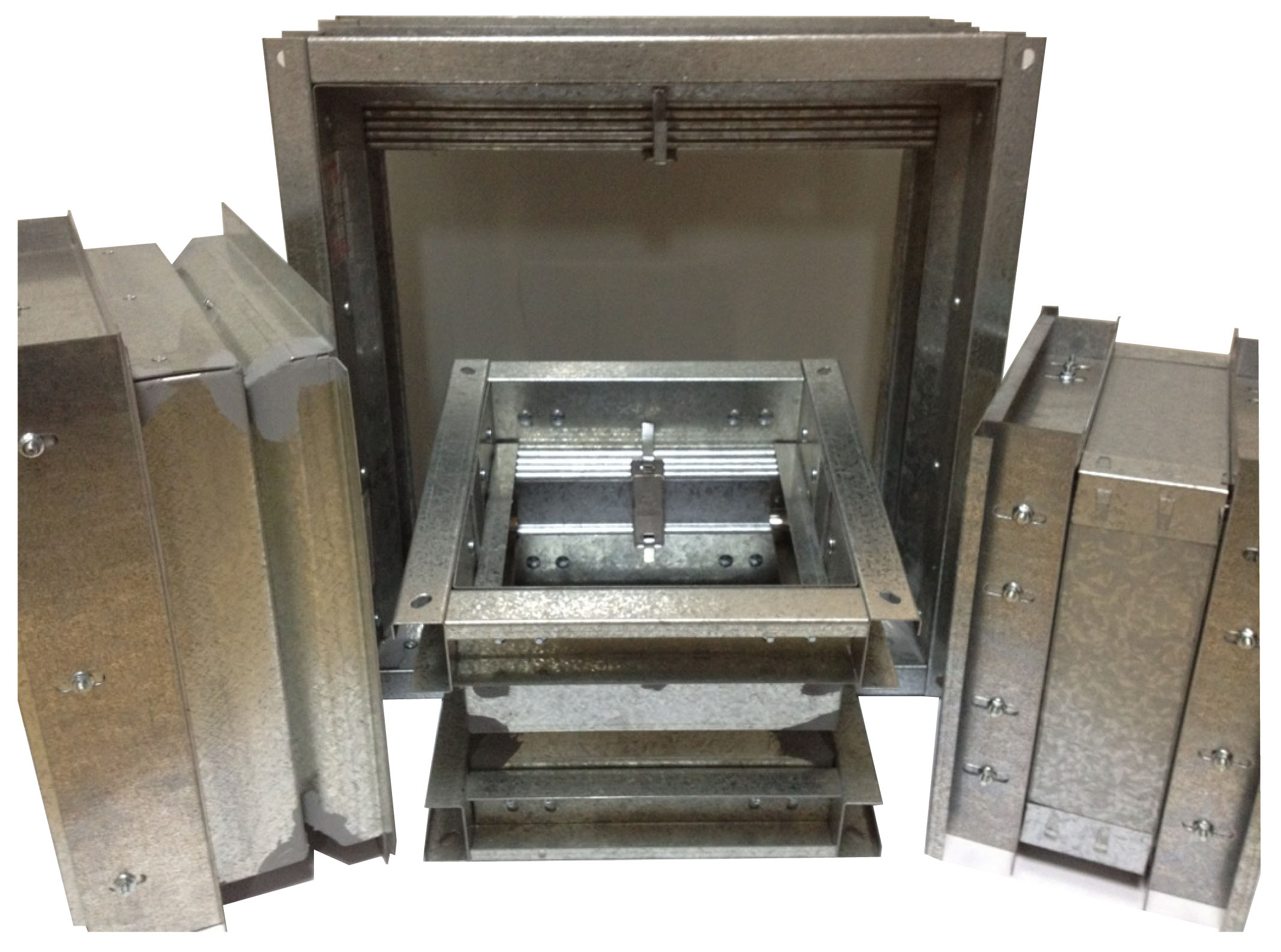

Model 4900 Curtain Type

Features

- Australian certified to AS1530.4-1997 by the C.S.I.R.O. in:

- Masonry walls for 4 hours. Sponsored investigation FSV-0094

- Concrete slabs for 4 hours. Sponsored investigation no. 1864

- Steel Stud Plasterboard partition for 2 hours. See Wall manufacturers instructions

- All galvanised steel construction

- Single (UL33 rated) fusible link

- Optional TDF/TDC type flanges available for 1 x leakage/breakaway point

- Low melting point bolts to be used.

- Optional patented Bullock metal expansion gap seals available for a factory set 10mm expansion gap

Manufactured sizes available

- Wall: 150mm x 150mm up to 4800mm x 4800mm

- Slab: 150mm x 150mm up to 750mm x 750mm (contains 2 x 301 S/S conforce springs)

Patented Bullock metal expansion gap seals

Optional patented Bullock metal expansion gap seals are standard on model 4900 Bullock Curtain Type Fire Dampers. Metal spacers allow the damper to be installed instu with a 10mm controlled expansion gap (AS1682.2-2015). This means no installation or inspection costs plus the elimination of health harardous fibres. (Aust. Patent #-624288)

Installation

Compliance with installation instructions is critical. Refer to separate wall type/slab type installation instructions to suit your requirements.

Maintenance

This model requires little maintenance once install. Refer to AS1851-2012 for detailed servicing procedures.

Typical specifications

Openings in fire rated walls or slabs shall be protected by a Bullock Model 4900 Curtain Fire Damper or approved equivalent. Dampers shall be provided where shown on drawings and wherever required to meet local regulations and must comply with AS1682.1-2015.

Dampers shall be installed in strict accordance with the manufacturer’s installation instructions, to comply with the certificates of test furnished by the manufacturer.

The damper’s construction must be in compliance with the tested prototype. The body being made with galvanized steel with any welds coated with cold zinc primer type paint to prevent rusting. The damper body must be strong and rigid to prevent operational damage during transport and/or installation on site.

The damper’s expansion gap must be constantly maintained with the use of the patented Bullock’s Metal Gap Spacer sealing system, complying with AS1682.2-2015 or an approved equivalent. Fusible link are to operate at 68°C or have an AS1890 rating.

Models available

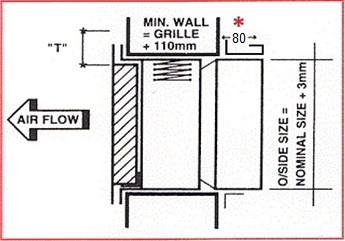

STYLE D

DUCT – TO – DUCT

Order should be read as follows:

Width (blade length) x Height x Wall thickness

Minimum wall thickness 80mm

*Channel width may increase with small walls

Flange sizes are as follows:

Sizes under 1200 x 1200 = 30mm

Sizes over 1200 x 1200 = 50mm

STYLE GR

GRILLE – TO – DUCT

Order should be read as follows:

Width (blade length) x Height x Wall thickness x Depth of recess

for grille x Flange.

*Channel width may increase with small walls

Minimum flange size “T”

(max W or H · 100) + 10

Refer as 1682.2-2012

STYLE GS

DUCT – TO – GRILLE

Order should be read as follows:

Width (blade length) x Height x Wall thickness x Depth of recess

for grille x Flange. Sized to be smaller than flange and grille

*Channel width may increase with small walls

Minimum flange size “T”

(max W or H · 100) + 10

Refer as 1682.2-2012